BIPV-ASA hollow photovoltaic integrated tile

一、Product specifications

Product specifications

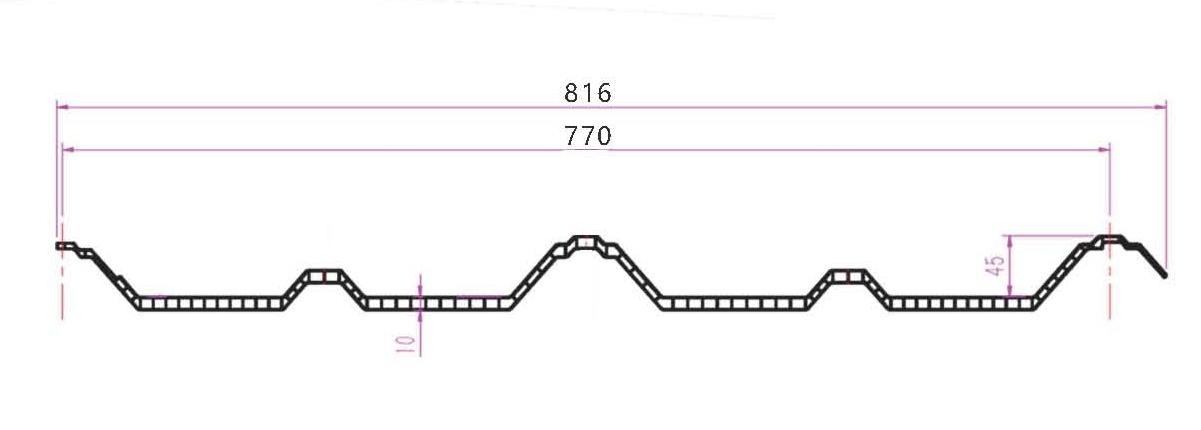

1.Width:Projection width 816mm Effective width 770mm

2.Thickness:10mm two layer

3.Surface color: white, blue, gray, brick red,

back color: white

4.Length: custom-made, recommended within 12m

二、Product advantages

1.1 The hollow photovoltaic integrated tile is made of modified PVC resin as the main base material, and the surface layer is made of weatherproof ASA resin by in-mold composite molding process.

1.2 The hollow photovoltaic integrated tile, with a“工” shaped reinforced lattice hollow structure between the surface and the bottom layer, not only has the function of enhancing the tile type rigidity, but also forms a natural air barrier, improve product sound insulation, heat insulation function.

Thermal insulation test

Test method:Place the specimen on the thermal insulation tester and record the temperature at the center of the specimen bottom surface every 20s.

1.3 Special buckle-fit structure for left and right side-wave design of hollow photovoltaic integrated tile, ensure that the waveform is regular and flat, and at the same time have the function of rainproof siphon leakage.

1.4 The hollow photovoltaic integrated tile has the characteristics of high strength, good rigidity, flame retardant and fireproof ( B1) , heat insulation test, acid and alkali corrosion resistance, heat resistance, waterproof, sound insulation, heat insulation, lightning protection and so on.

1.5 The hollow photovoltaic tiles can be used as roofing tiles alone or with the company's aluminum alloy trapezoidal fixtures, which are suitable for mounting solar cell,the special wave spacing design is especially suitable for the full installation of photovoltaic panels, each 10,000 square roof can be installed about 1.4 MW, effective utilization rate.

三、Application

(1)New construction of corrosive and non-corrosive industrial plant roofing.

(2)Large purlin distance (≤1200mm) industrial workshop roof, replace the corrosion of color steel tile roof.

(3)Suitable for installation of distributed photovoltaic panels, whether corrosive or non-corrosive plant, roof tiles have the same life as photovoltaic panels.

四、Solar cell installation

4.1 In the design of roof structure, the appropriate purlin spacing is designed in advance according to the wave spacing of ASA hollow photovoltaic integrated tile, the size and specification of photovoltaic panel, and the installation direction of photovoltaic panel, it can be installed directly on the ASA hollow photovoltaic integrated tile without U-shaped guide rail.

|

Mainstream 540 solar cell |

|

|

Component brand |

540 Component dimensions |

|

Jing ao |

2279×1134×35mm |

|

Ronki |

2256×1133×35mm |

|

Aerospace electromechanical |

2279×1134×35mm |

|

Zhongli Tenghui |

2279×1134×35mm |

|

Atez |

2261×1134×35mm |

4.2 The recommended installation distance for Type 540 solar cell is 1154mm for purlins and 770mm for trapezoidal fixtures.(图1)

图1

4.3 The recommended installation distance for Type 540 solar cell is 766mm for purlins and 1155mm for trapezoidal fixtures.(图2)

图2

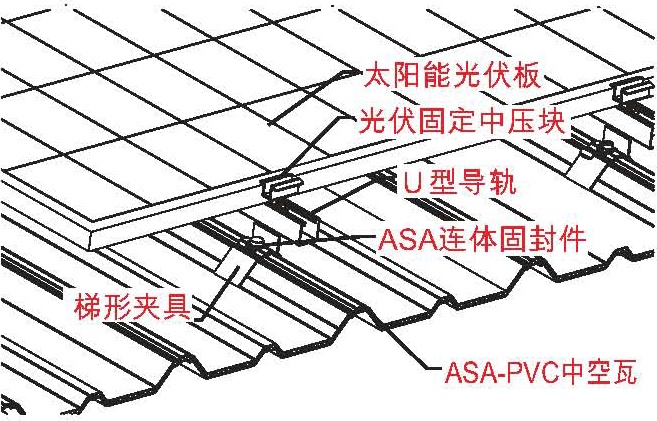

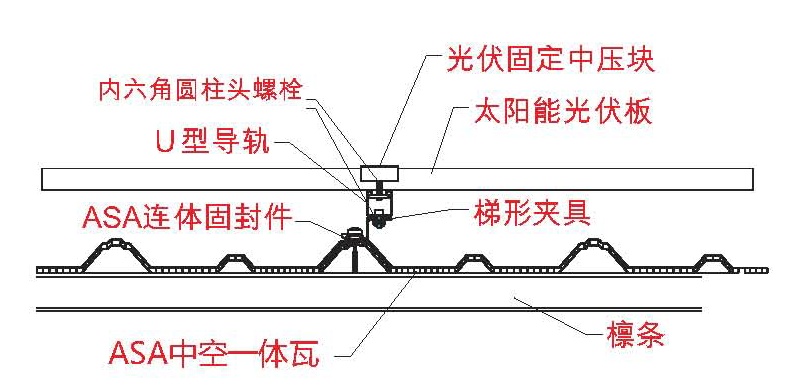

4.4 If the purlins do not match, the trapezoidal fixture and U-shaped guide rail combination can be used for installation.

The U-shaped guide rail must be installed perpendicular to the purlins, and the trapezoidal fixture must be installed on the purlins.(图3)

图3

五、ASA hollow photovoltaic integrated tile common accessories

|

Part name |

Material |

Introduction |

Introduction |

|

ASA Solid Seal Assembly |

ASA |

Used for roof tile fixed installation, protection of screws, delay the aging of screws rust, improve service life. |

|

|

Hexagonal drilling screws ST7.5×90 |

Corrosion-resistant modified zinc plating |

Used for mounting, the roof shingles are fixed to the bottom supporting purlins. |

|

|

Right ridge tile |

ASA hollow tile |

Used for roof ridge, connect two slope waterproof. Size:300*300*770mm |

|

|

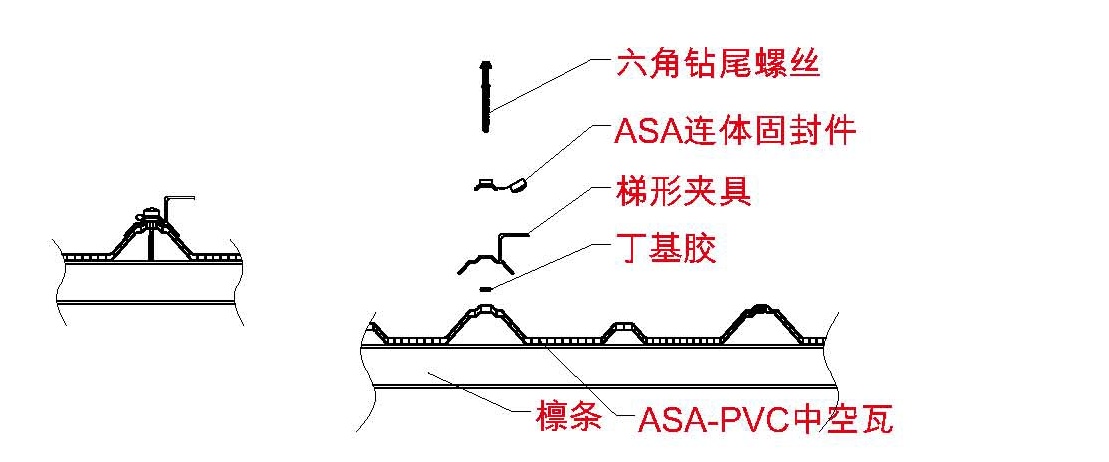

Trapezoidal fixture |

Aluminum alloy |

The utility model has the advantages of convenient combination of photovoltaic bracket accessories, labor-saving on-site installation, greatly reducing the construction cost and improving the engineering efficiency. |

|

|

Photovoltaic fixed medium pressure block、Plastic wing nut、M8 bolt kit |

Aluminum alloy |

Used for solar cell mounting. |

|

|

U-shaped guide rail |

Galvanized or aluminum alloy |

With the photovoltaic fixed press block, used for photovoltaic panel installation and fixation. |

|

六、Points for attention in installation of ASA hollow Photovoltaic integrated tile

6.1 Installation tools

Drill Angle Grinder Cable Box Tape measure, yardstick Gloves

6.2 Installation sequence

Roof Slope

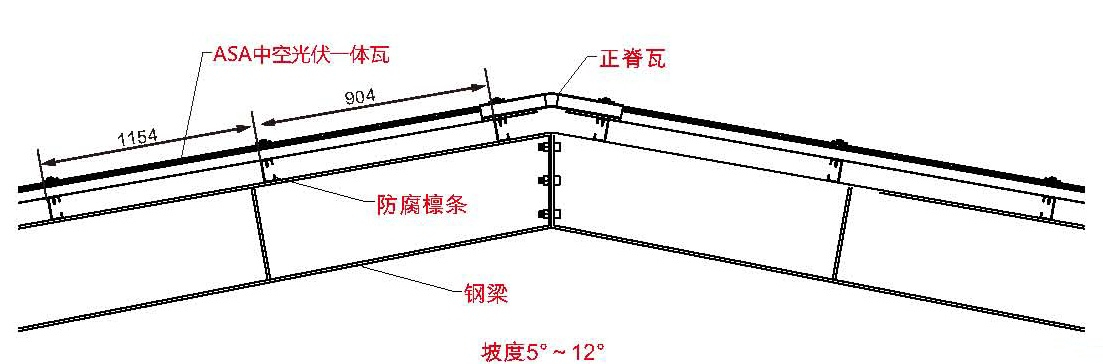

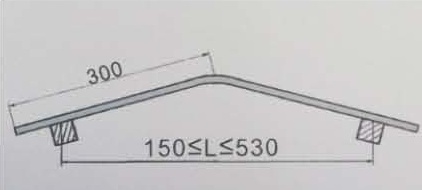

ASA hollow photovoltaic integrated tile is suitable for sloping roof with gradient of 5 ° ~ 20 °.(图4)

图4

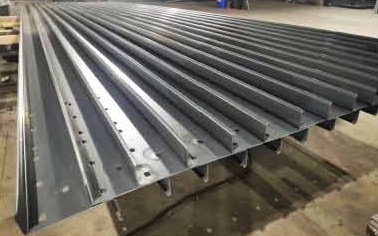

Redwave brand C-type plastic steel anti-corrosion purlins

Purlin requirements

1.Purlins are recommended to be made of Fulant brand C-type plastic steel corrosion-resistant purlins. If other purlins are used, the surface of purlins should be treated with anti-corrosion.

2.Level:The purlins are checked and leveled before installation of main tile. The level of purlins is checked one by one. The height difference between purlins is controlled within ± 5mm.

Thread

Before installation should be based on the situation of the site roofing laying, so that help installation watt-hour to achieve horizontal and vertical, to ensure installation quality and achieve aesthetic results.

Install main tiles

1.When installing the main tile, no matter what structure and shape of the roof, the side of the main tile should be close to the construction line and installed from one side.The first tile installation is particularly important, must ensure that the side of the tile and construction line vertical shall not tilt. After positioning, the lower end purlins are positioned in the center of the tile (wave crest) to secure the tile.

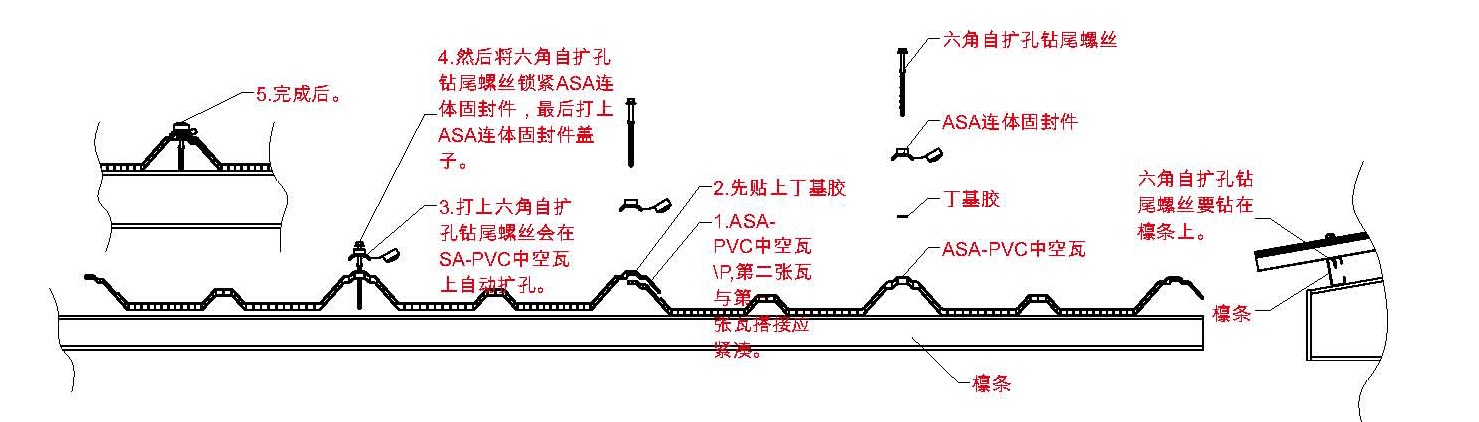

2.When installing the second tile to pay attention to the second tile and the first tile lap should be compact, the gap between the occlusal to close.At the same time, pay attention to whether the two sides of the tile are perpendicular to the construction line.Install the third and fourth tiles according to this method. After the fourth tile is installed, re-check the level of the four tiles, the vertical situation, whether the lap is compact, after determining the accessories can be installed in order.(图5)

图5

3.When installing the main tile, the two sides should be installed at the same time to ensure that the two sides of the main tile peak and peak completely opposite.One is to speed up the construction process, and the other is to avoid the normal installation of ridges caused by errors.

4.Fixed Way:The steel purlin adopts drilling tail nail and the wood purlin adopts self-tapping wood screw.Screw and special waterproof fitting (ASA connecting fastener) to tie on the wave crest.

5.When installing triangular inclined roof with four-slope roof, the first tile should be installed from the middle, and then installed to the two sides respectively.After the main tile is installed, the spare part is cut with an electric cutting saw to facilitate the installation of various types of ridge tiles.

6.If you want to install solar cell, add trapezoidal fixtures.(图6)

Positive Ridge tile mounting

The positive ridge tiles are installed on the roof ridge, starting from one side of the main tile area, and a waveform is lapped between the two positive ridge tiles.(图7)

图7

图7

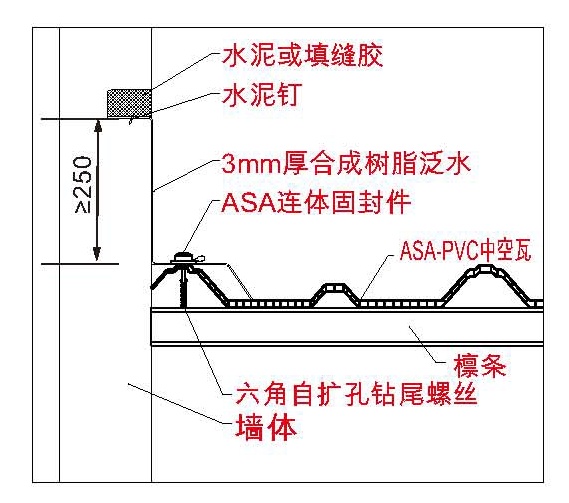

Flooding at the junction of the roof and the daughter wall

Mode 1:The flooding board is made of metal plate or synthetic resin plate according to the field size processing.Make a hole about 50 x 50mm in the wall and put the flooding board into the hole,one end is fixed to the hole in the wall by a spot lamp (or cement nail) , and the other end is fixed to the tile wave.(图8)

图8

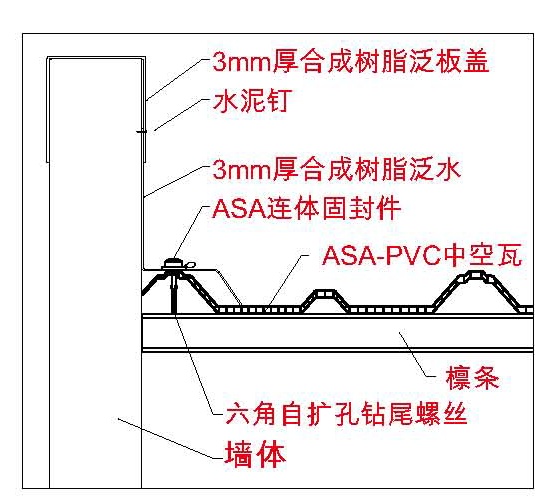

Mode 2:The flooding board and flood plate cover plate is made of metal plate or synthetic resin plate according to the field size processing.First, put the flood board close to the wall, then cover the flood board in the flood board close to the wall, and then hit the cement nails, fixed at the other end of the tile wave.(图9)

图9

Other points to note

1.The installer needs a certified professional to ensure that the product is safe to use.

2.Installer must wear gloves, safety helmet, safety belt and other tools, make a good job safety protection measures.

3.In bad weather, installation must be carefully.

4.When installing, walk on the tiles, try to step on the purlins, avoid stepping on the edge of the tiles.

5.It is forbidden to contact with strong acid and strong alkaline substance.

6.Do not bend the tiles too much to avoid damage.

7.The thermal expansion and contraction of ASA hollow photovoltaic integrated tile is different from that of steel.Reserve expansion space and pay attention to the depth of embedding, otherwise it may lead to tile deformation, fracture.

8.Used neutral glues and suitable liner materials to prevent water leakage.

Product Message

WRITE A MESSAGE TO US

Founded in 1988, Guangdong Hongbo Building Materials Technology Co., Ltd. is a national brand manufacturer of PVC roofing materials in China.

Contact information

Guangdong Hongbo Building Materials Science and Technology Co., Ltd.

Foshan Ketelong Building Materials Import and Export Co., Ltd.

Address:

No.6 (f1-f9), South B community, central science and Technology Industrial Zone, Leping Town, Sanshui District, Foshan City, Guangdong Province

E-mail:

CopyRight @ 2011-2021 Guangdong Hongbo Building Materials Science And Technology Co., Ltd. 粤ICP备13029100号 Powered by www.300.cn

400-161-3388

400-161-3388

Feedback

Feedback