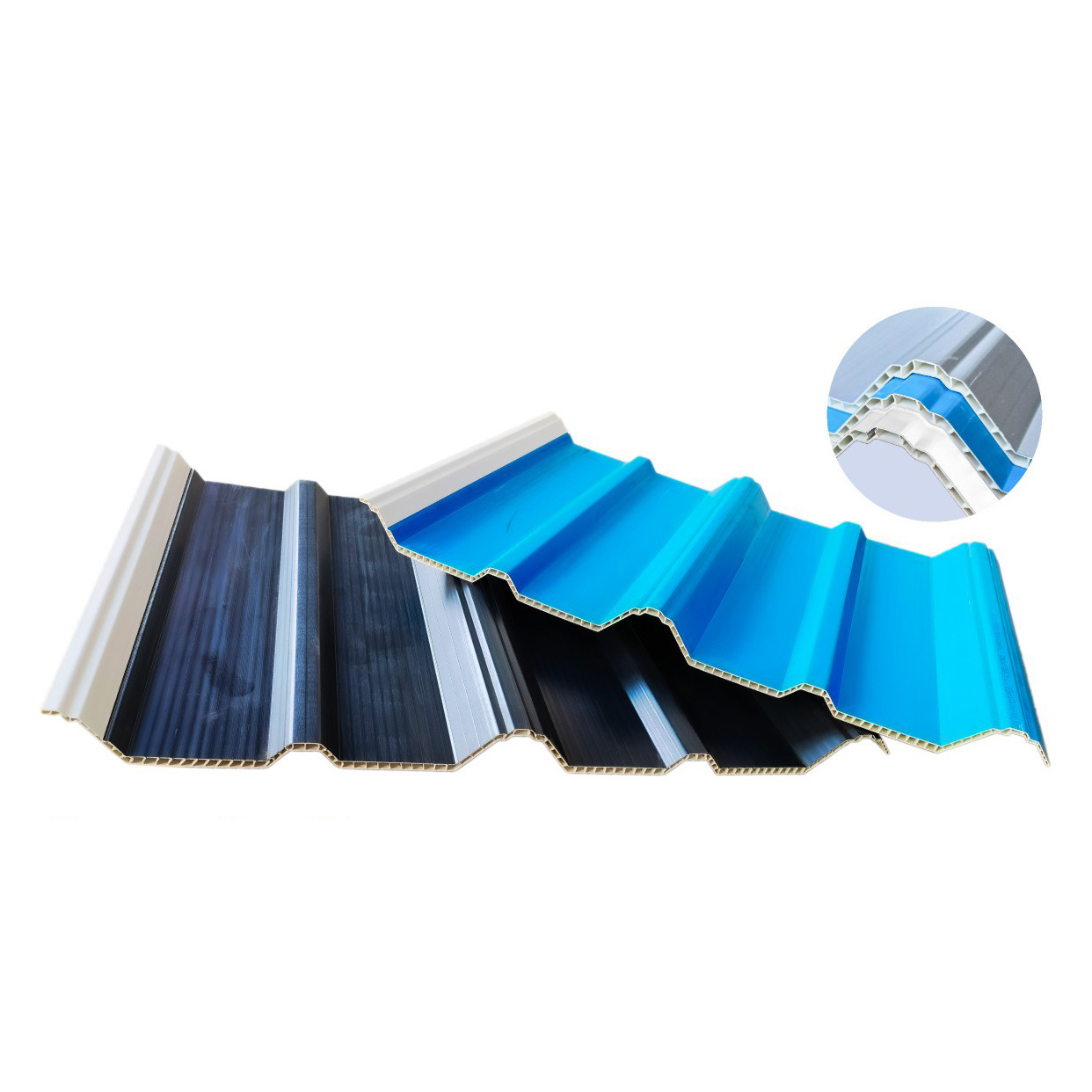

ASA hollow photovoltaic tile

Hollow photovoltaic tiles use modified PVC resin as the main base material, with a weather-resistant ASA resin surface layer, formed by in-mold compounding, and have a service life of ≥25 years.

- Description

- Product introduction on the left

-

Hollow photovoltaic integrated tiles use modified PVC resin as the main substrate material, with a weather-resistant ASA resin on the surface. They are made using an in-mold compounding process and have a service life of ≥25 years.

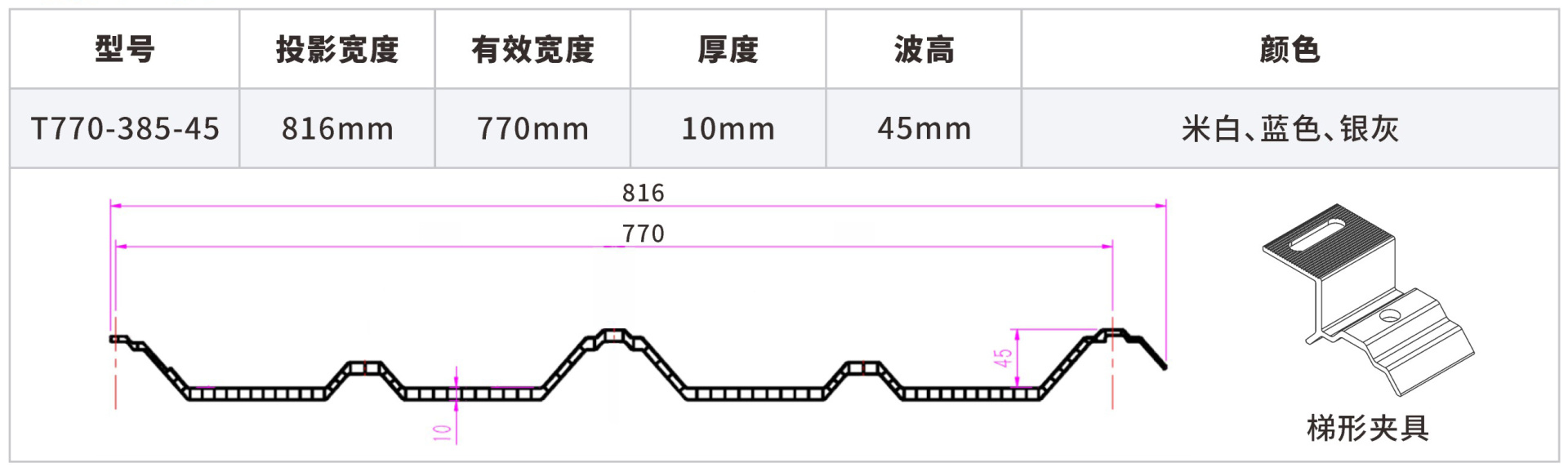

I. Product Specification:

II. Product Advantages:

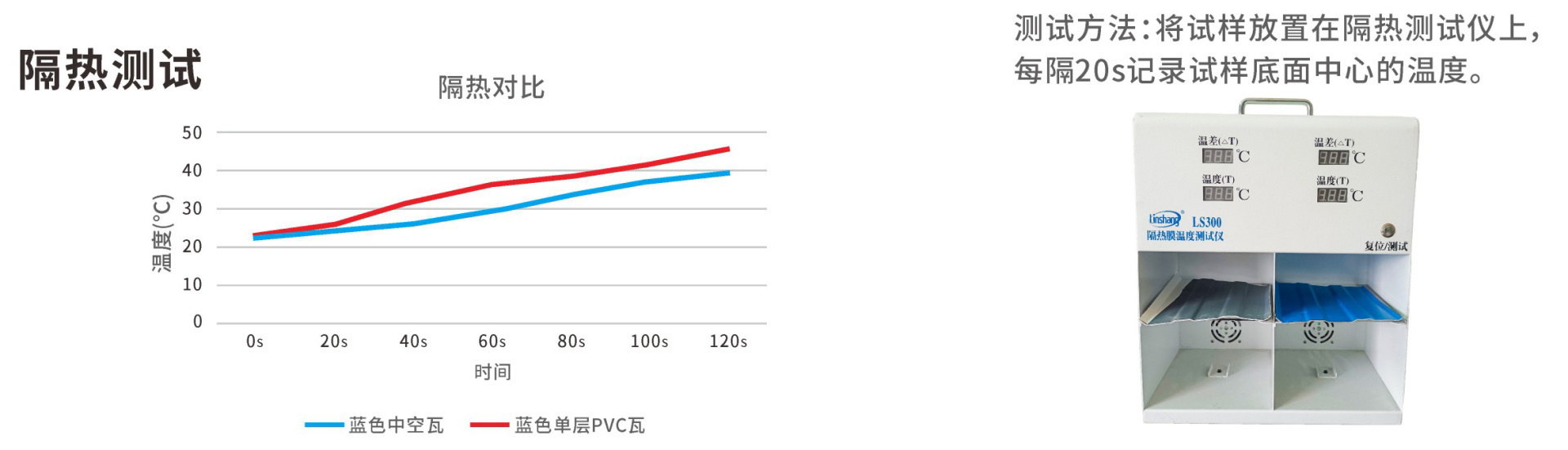

1. Hollow photovoltaic integrated tiles have a "工"-shaped reinforcing rib grid hollow structure between the top and bottom layers. This not only enhances the tile's rigidity but also creates a natural air barrier, improving the product's sound insulation and heat insulation functions.

2. The special interlocking structure with a wave design on the left and right sides of the hollow photovoltaic integrated tiles ensures a neat and even wave shape while also having a function to prevent rainwater from siphoning and leaking.

3. Hollow photovoltaic integrated tiles have the characteristics of high strength, good rigidity, fire retardancy (B1 level), heat insulation, acid and alkali resistance, heat resistance, waterproofness, sound insulation, heat preservation, and lightning protection.

4. Hollow photovoltaic integrated tiles can be used as roof tiles alone or can be used with the company's developedaluminum alloy trapezoidal fixture, which can adapt to the installation of solar photovoltaic panelsWith a suitable eaves distance design, no "rails" are needed for full coverage of photovoltaic panels. Approximately 1.5 MW can be installed per 10,000 square meters of roof area, resulting in high utilization efficiency.

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!