Environmental Pioneer: Application and Advantages of Fusuo Anti-corrosion Board in Green Buildings

Release time:2024-12-12

Preface

In today's era, the issue of environmental protection is becoming increasingly severe. Green and environmentally friendly building materials are an important way to achieve green buildings. With the promotion and research and development of green materials, a variety of environmentally friendly building materials have appeared on the market. By choosing the right materials, customers can not only reduce the negative impact on the environment but also improve building energy efficiency, bringing more long-term benefits.

Application of Fulu Corrosion-Resistant Board in Green Buildings

VOCs mainly come from coal chemical industry, petrochemical industry, fuel paint manufacturing, solvent manufacturing and use. Most VOCs are toxic, irritating, teratogenic and carcinogenic, harming human health.

AndZero VOC emissions in the production process of powder Fulu boardIt is known as "China's new generation of color-coated plates". Its appearance will push China's traditional "color-coated plate" industry into the 2.0 era.

Funite powder Fulu color-coated plate uses 55% aluminum-zinc coated substrate, which is double-sided sprayed with high molecular weight thermosetting powder coating,After high-temperature melting and plastic and chemical crosslinking, it is solidified into a new generation of dense and hard color-coated plates。

As an upgraded product of traditional color-coated plates, Fulu corrosion-resistant board has achieved significant performance improvements in many aspects, which can extend the service life of buildings, reduce maintenance costs and frequency, and comply with the sustainable development concept of green buildings.

Seven Advantages of Fulu Corrosion-Resistant Board

01. Acid and alkali resistance

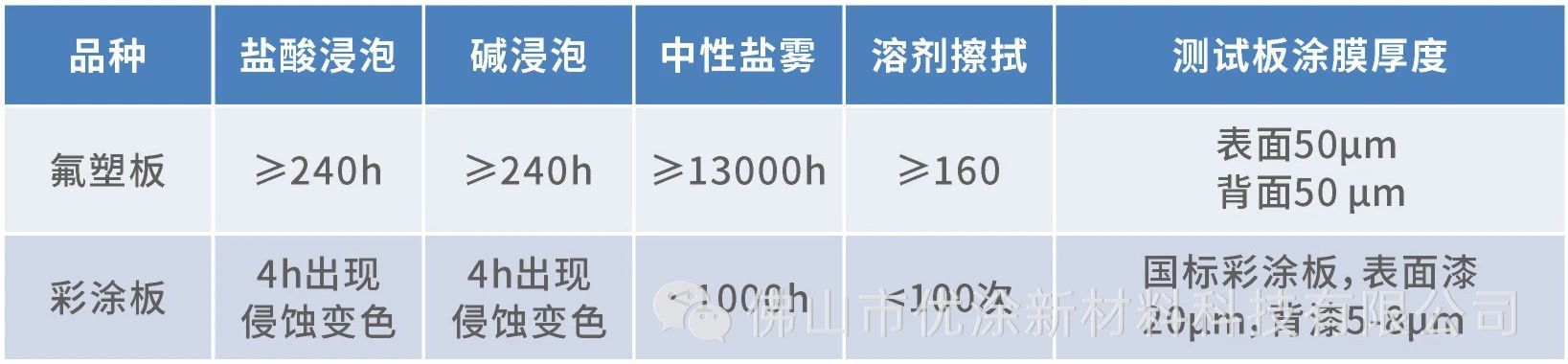

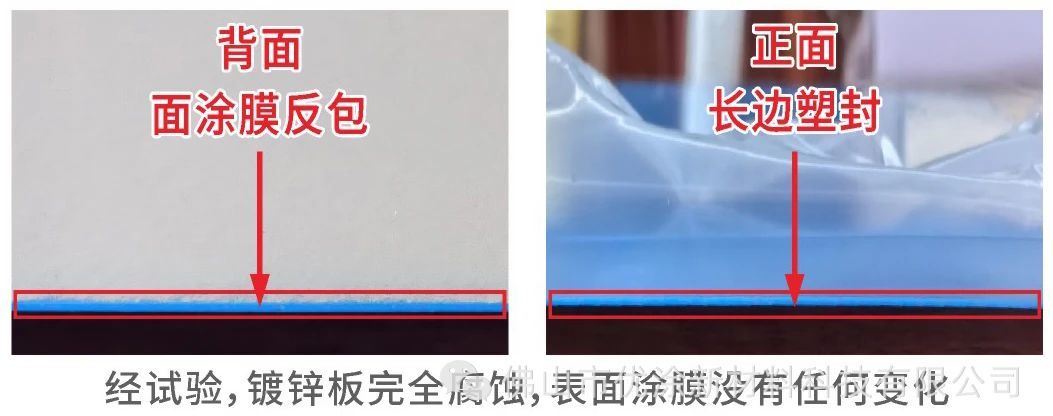

High molecular weight thermosetting powder coating has super strong corrosion resistance, and the back coating thickness can reach ≥50-120μm (national standard color-coated plate back paint 5-8um). At the same time, the long side of the plate is "plastic-sealed", and the corrosion resistance of the edge of the plate is further improved.

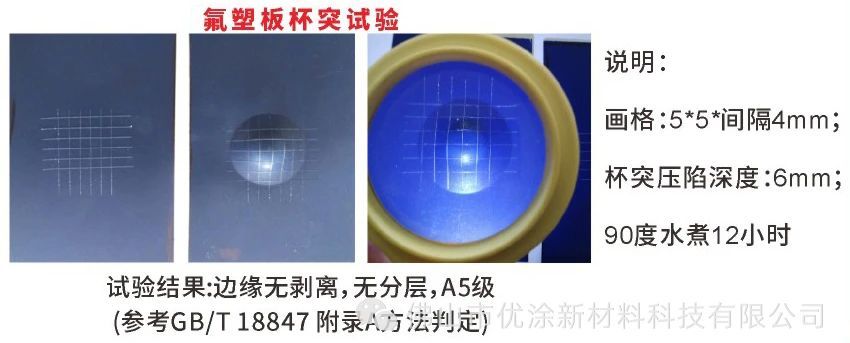

02. Bending resistance

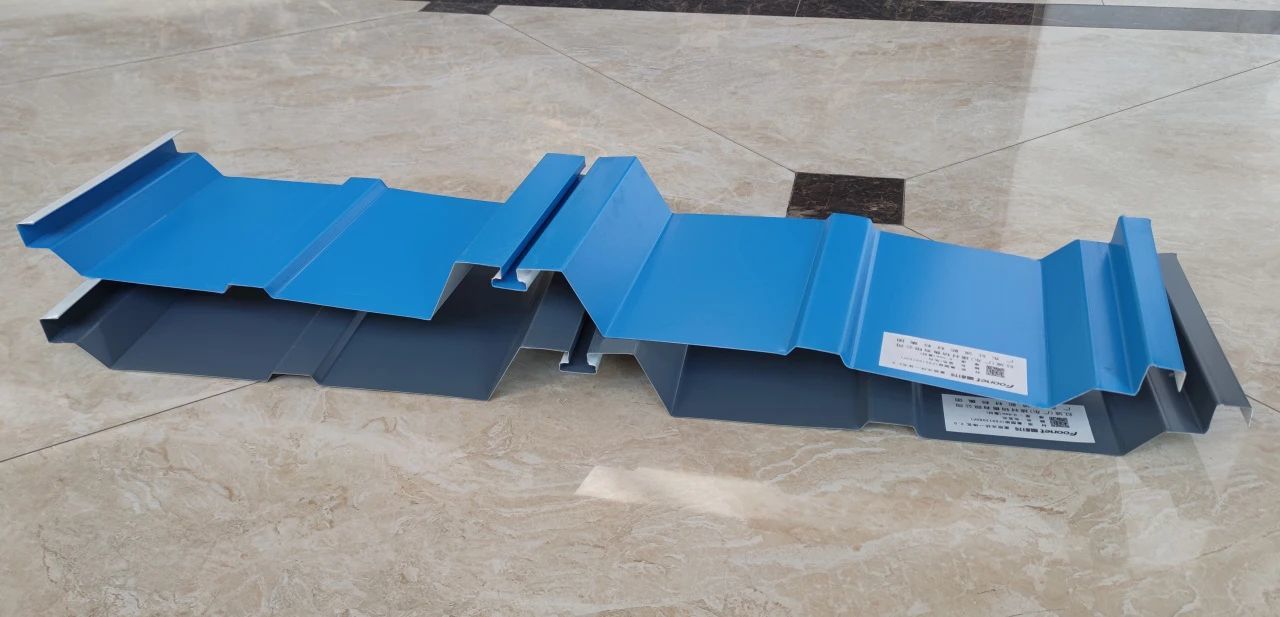

0T, 1T bending, the coating does not crack or peel off, and can be cold-processed into all plate types.

03. Anti-aging

After 3600 hours of artificial accelerated aging test, the surface color remains unchanged, and no powdering phenomenon has occurred.

04. Scratch resistance

The coating hardness reaches 2H after testing, while the color-coated plate is only HB.

05. Fire resistance

The fire performance reaches A2 level after testing.

06. Sound insulation and heat insulation

Due to the large surface coating thickness, the noise is lower than that of color-coated plates during rain, and the heat insulation and sound insulation performance is better.

07. Various colors

Various colors can be produced, and the high-film thickness melting and plastic process makes the plate surface color more full and delicate.

Applications of Fulu Corrosion-Resistant Board

Fulu corrosion-resistant board can be widely used

Steel plants, power plants, coal yards, food processing, coastal factories, chemical industry, pharmaceuticals, papermaking leather, printing and dyeing, casting, ceramics, chemical fertilizers, non-ferrous metal smelting, electroplating, salt fields, acid plants, animal husbandry and breeding, etc.

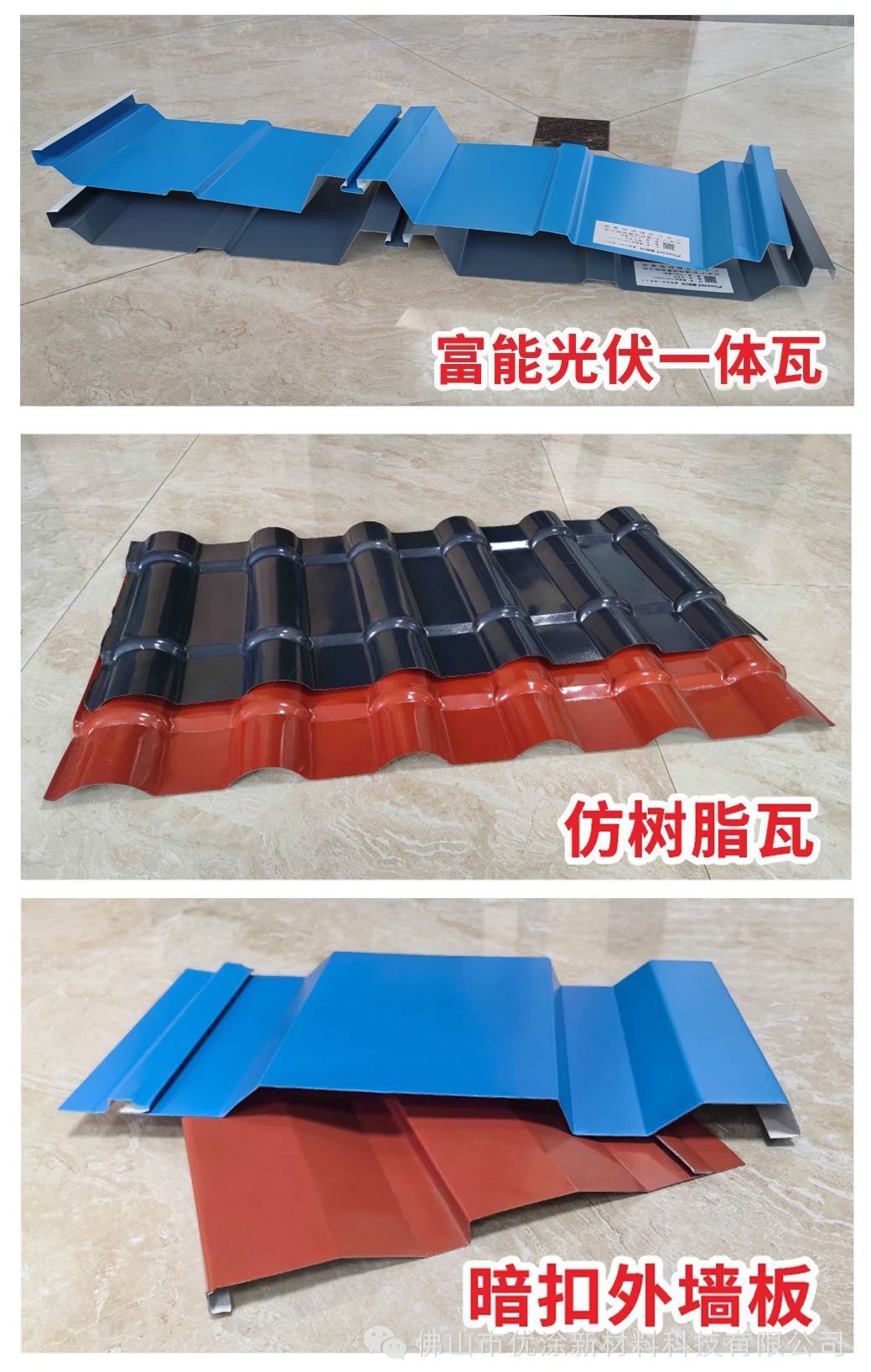

Fulu corrosion-resistant board has good processability

It can be cold-bent into shape: Funeng photovoltaic integrated tiles, concealed buckle exterior wall panels, imitation resin tiles, T840 and Jiaochi 760 and all plate types.

END

In summary, Fulu corrosion-resistant board has made progress in technological innovation, performance improvement, application expansion, and environmental protection and sustainability. It not only meets the functional needs of buildings but also makes positive contributions to environmental protection.

Related News