Click to view! These steps are essential for roof tile construction!

Release time:2024-12-13

A Tweet Reveals the Secrets of Roof Construction

- Construction Industry Dry Goods Knowledge -

Stadium Roof Replacement

Roof construction is often seen in many different engineering Cases! Factory construction, carport construction, drying shed construction... So how to choose materials? How to build? How to save money? In this tweet, we will share the dry goods knowledge of roof construction with you using real engineering Cases!

Construction Site

Choose the right tile material based on the application environment

We generally divide the application environment of roofing into corrosive and non-corrosive!Corrosive application environments are generally divided into internal corrosion (livestock farms, fertilizer plants, etc.) and external corrosion (coastal area factories, heavy industrial area factories, etc.). Non-corrosive application environments generally include warehouses, markets, etc.。

Different environments naturally require different tile materials! For corrosive application environments, we generally recommend usingFluoroplastic sheetas the substrate material, orAPVC anti-corrosion composite corrugated tile,This type of tile is a product specially designed for corrosive application environments, and the Price is relatively high! For non-corrosive application environments, we can generally chooseAluminum magnesium zinc、orZinc aluminum magnesiumas the substrate material! These tile materials have a relatively low Price!

Fluoroplastic sheet

Aluminum magnesium zinc substrate pressed Funeng tile

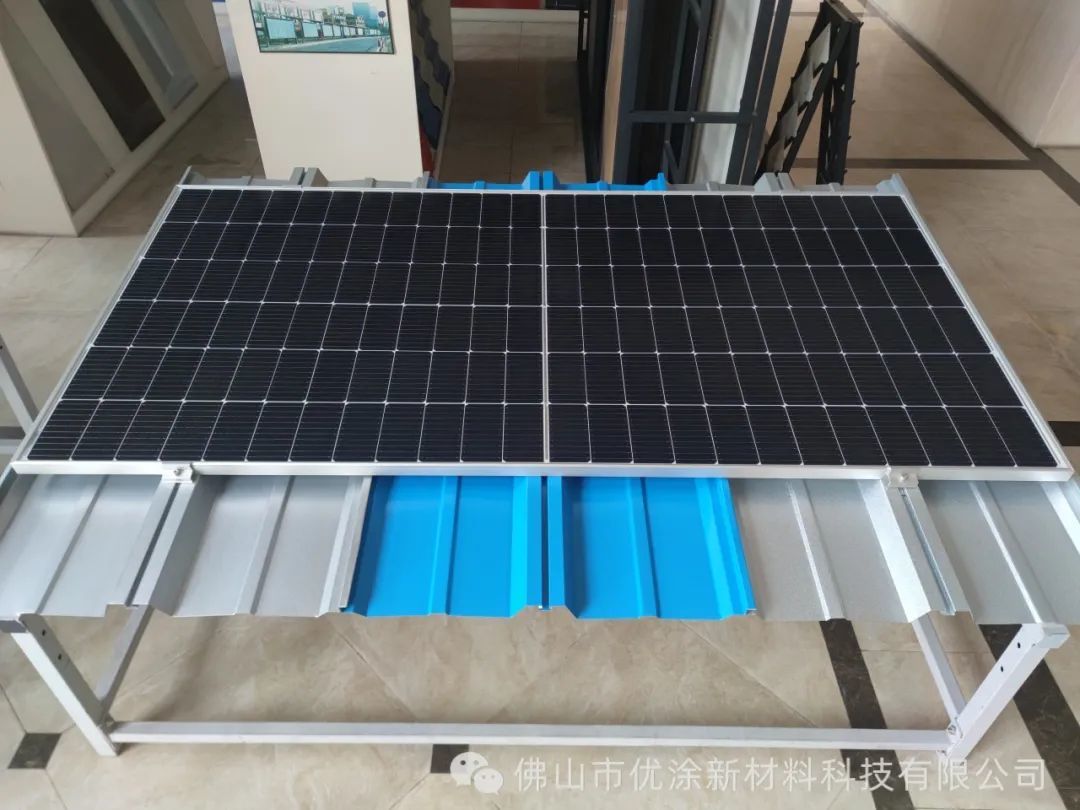

Our engineering Case today is a gymnasium, which belongs to a non-corrosive application environment, so we can choose to useAluminum magnesium zinc as the substrate pressed 820 tile!The Price is cheap, but it still has excellent weather resistance and corrosion resistance!

Construction Site

Aluminum magnesium zinc 820 tile cost-effective tile

Aluminum magnesium zinc 820 tile

Aluminum magnesium zinc 820 tile is suitable forNon-corrosive application environmentsProduct. This product is not only cost-effective, but also has two major advantages -Corrosion resistance and weather resistance!

1. Corrosion resistance

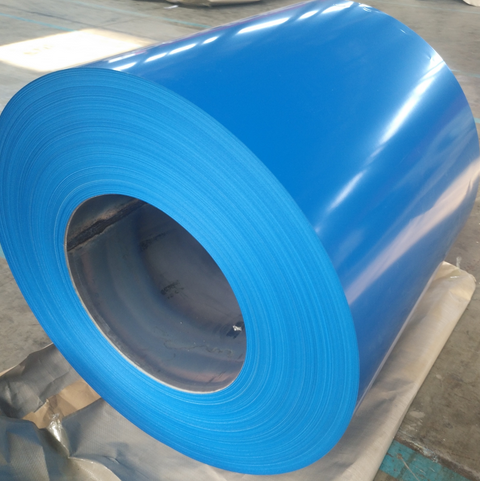

Aluminum magnesium zinc plate

Aluminum magnesium zinc plate products belong to“High aluminum”content range,The aluminum content in the coating is as high as 55%,and the magnesium component is very stable and can form a fine protective film,Tile materials pressed with aluminum magnesium zinc plate as the substrate have excellentCorrosion resistance!Its corrosion resistance is more than 5 times that of pure zinc-plated products of the same grade coating weight!

2. Weather resistance

And this product has excellentWeather resistance!Aluminum magnesium zinc 820 tile in the face ofSunlight, temperature changes, wind and rain, etc.,The product can still perform stable characteristics and durability!

Three-step construction dry goods sharing

Want to install the tileHeat insulation!Want to lower the indoor temperature! These steps are crucial!

1. Pull the steel wire

Construction Site

Construction personnel first pull the prepared steel wire net, which is used to support the glass wool.

2. Lay the insulation layer

Construction Site

Then lay glass wool on the steel wire, which can play a heat insulation role!

3. Cover and fix the tiles

Construction Site

After laying the glass wool, you can cover the tiles on it! Then use the screws matching the red wave to fix it, and the installation is complete! Convenient and fast!

Welcome to follow

Guangdong Hongbo

Welcome to follow Hongbo, thousands of engineering Cases are waiting to be shared with you! To reveal the secrets of the roofing industry for you!

Related News